Industrial dust collectors for fine suspended dusts

Du-puy offers a variety of dust extraction systems, starting from portable machine to complex plants. The industrial dust collectors are the ideal machine for the recovery of fine and suspended dust in the working environment. These industrial dust extractors are designed according to the specifics features of the customer's production plant for maximum efficiency. We also build central dust collection systems to maximise the efficiency of your production facility. Our dust extractors increase profitability through reliable, energy-efficient and production-focused systems. Our wide range of industrial dust extractors and dust collectors, including filtration systems, deliver remedies for numerous industrial dust control challenges. Safety is also at the forefront when designing, installing and maintaining industrial dust extraction systems and we will always comply with HSE standards, ensuring worker protection. Ask the DU-PUY experts for advice. Whether your facility’s processes involve metals, chemicals or other materials, Dupuy's dust collectors intervene to keep your facility clean. Our dust collection systems are used successfully in a wide variety of industries as woodworking, sandblasting, metalworking, food, chemical and pharmaceutical.

Dedust 1

Mobile and compact dust collector

Dedust 2

Dust collector for fine suspended dusts

Dedust 4

Dust Collector for fine suspended dusts

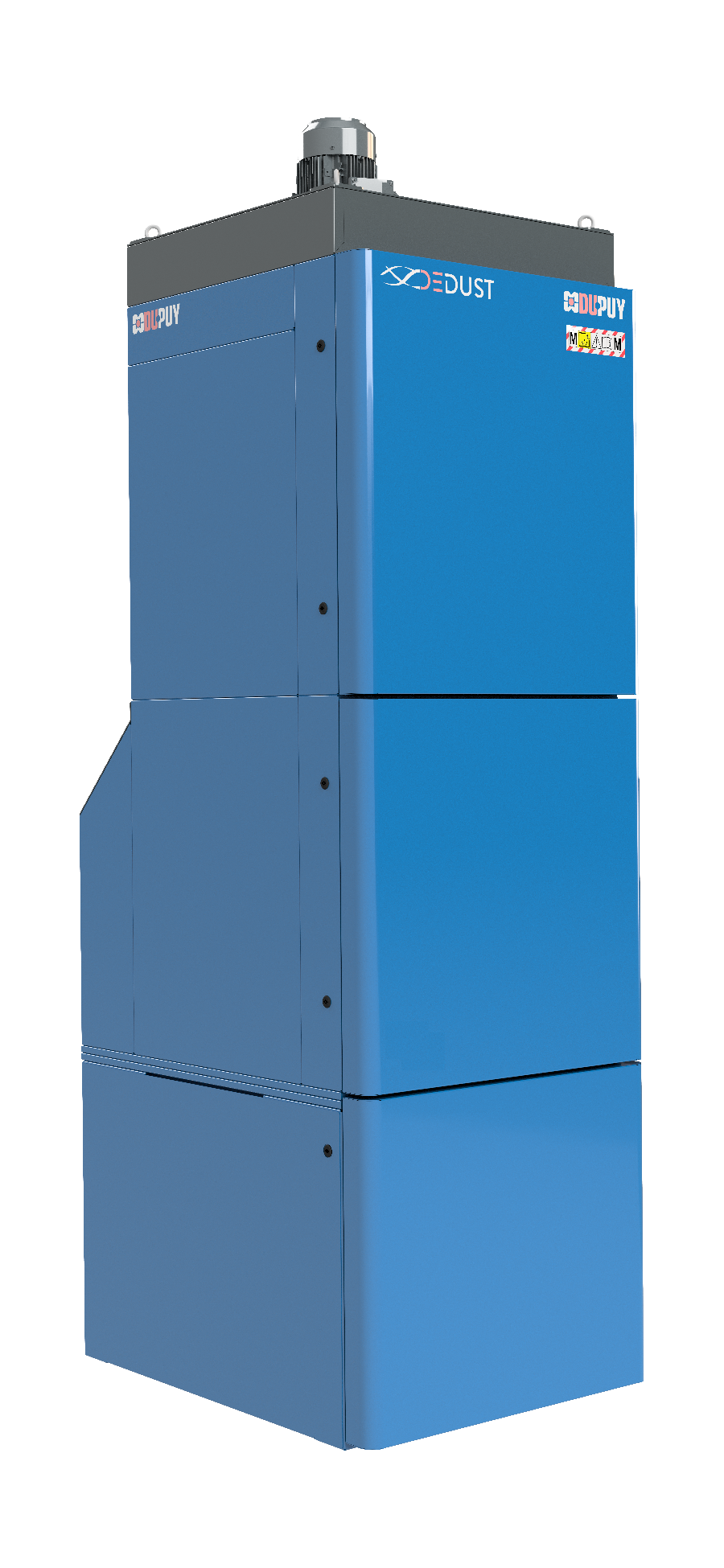

Dedust 8

Dust Collector for central vacuum systems

Industrial Dedusting units

Industrial dust collectors are high air flow vacuum systems (from 1350 to 5400 m2 / h). Our dust cartridge filters can filter and clean high volume of air in an extremely compact format. These dedusting units are designed for extraction and filtration of fumes and suspended powders in production environments in any type of industrial fields.

- Welding fumes

- Marking and laser cutting dusts

- Flours from food industry processing

- Dusts and vapors from chemical industry processing

- Metal surface treatment

- Wood processing

These dedusting machines are usually designed according to the needs of our customers' production plant.

The industrial dust collectors represent the ideal choice for working environments that present the necessity of a control of the dust in suspension thanks to the possibility to configure one or more articulated arms for the localized aspiration. The cartridge filters used for dust filtration are highly efficient and ensure continuous, safe and efficient work. Our dust collectors for air purification and filtration are equipped with an automatic air cleaning system with constant control of clogging and of filtration and suction performances.

It's possible to set each dust extractors in according to explosion safety requirements (ATEX directives). The filtration unit could be protected against dust explosion effects by flameless explosion venting and explosion decoupling.

Benefits of a Dupuy's dust collection system:

Improve clean and safety of the working environment

No more equipment with dust and debris inside, increasing productivity

Better quality of processing, reducing cross contamination

Respect of regulations about the quality of the air.

Happier employees, better condition of work means satified employees

Application

Technical Datasheet

| Description | Unit | DEDUST 1 | DEDUST 2 | DEDUST 4 | DEDUST 8 |

|---|---|---|---|---|---|

| Voltage | V - Hz | 400 - 50 3~ | 400 - 50 | 400 - 50 3~ | 400 - 50 |

| Power | kW | 1,1 | 1,5 | 3 | 5,5 |

| Electrical protection | IP | 55 | 55 | 55 | |

| Max waterlift | mmH2O | 144 - 121 | 142-115 | 270 - 191 | 350 - 245 |

| Max air flow | m3/h | 2100 - 1350 | 1350 - 2400 | 2100 - 3800 | 3000 - 5400 |

| Suction inlet | mm | 150 | 1 x 200 - 2 x 150 | 1 x 250 | 1 x 300 |

| Noise level (EN ISO 3744) | dB(A) | 69 | 70 | 68 | 74 |

| Filter Type | Cartridge | Cartridge | Cartridge | Cartridge | |

| Surface Diameter | cm2-mm | 100.000 - 325 | 200.000 - 325 | 400.000 - 325 | 800.000 - 325 |

| Material - Efficiency | IEC 60335-2-69 | Polyester - ANT M | Polyester - ANT M | Polyester - ANT M | Polyester - ANT M |

| Cleaning system | Automatic PN | Automatic PN | Automatic PN | Automatic PN | |

| Cartridge number | 1 | 2 | 4 | 8 | |

| Collection tank | Steel | Steel | Steel | Steel | |

| Discharge system | Roll-out container | Roll-out container | Roll-out container | Roll-out container | |

| Capacity | lt. | 5 | 30 | 90 | 90 |

| Dimensions | cm | 88 x 83 x 106h | 115 x 82 x 170h | 120 x 105 x 230h | 120 x 110 x 330h |

| Weight | kg | 145 | 235 | 350 | |