LUBE Hybrid Lubricant LHL®

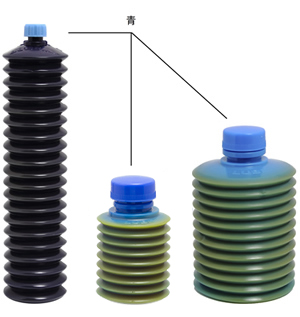

400ml

[LHL-X100-4]

200ml

[LHL-X100-2 ]

700ml

[LHL-X100-7]

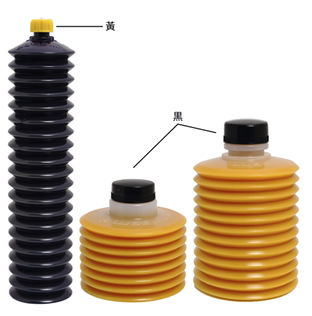

400ml

LHL300-4

400ml

[LHL300-4S]

700ml

[LHL300-7]

A lubricant that has the advantages of both oil and grease

developed to solve the following problems of grease:

In order to solve the above problems, LHL-300 was developed as a lubricant suitable for the environment and conditions in which machine tool components are used.

Features

LHL has the advantages of both oil, such as excellent non-adherence, liquidity and intervention; and grease, such as excellent extreme pressure resistance, wear resistance, water resistance and retention.

=Oil type integration

◆Operating temperature limit/LHL300 -20℃〜+130℃ ◆Operating temperature limit/LHL- X100 -20℃〜+150℃

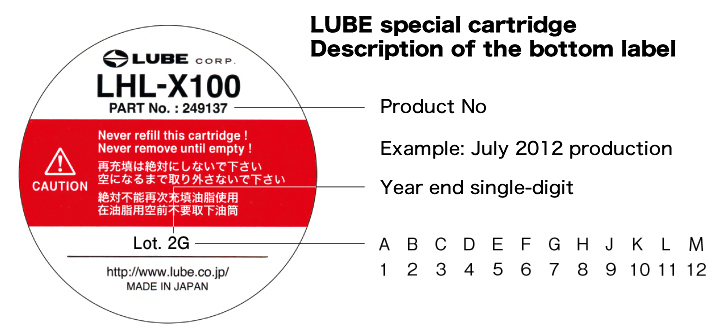

Model

| Model | Part Number | Capacity | Color of Grease | Consistency |

|---|---|---|---|---|

| LHL300-4S | 249113 | 400ml | yellow | 0 |

| LHL300-7 | 249112 | 700ml | 0 | |

| LHL-X100-2 | 249139 | 200ml | Brown | 0 |

| LHL-X100-4 | 249136 | 400ml | 0 | |

| LHL-X100-7 | 249137 | 700ml | 0 |

LHL-X100 Performance Test Data

- The excellent load-carrying capacity and wear resistance prevent seizures and excessive wear. Excellent water resistance and corrosion resistance

- LHL is versatile to emulsification and softening even when water is introduced. In addition, its excellent corrosion resistance prevents the development of rust and pitting.

- Developed as lubricants for centralized lubrication systems, LHL has excellent transport property and supplying LHL in the right amount at the right time guarantees ideal lubrication effects.

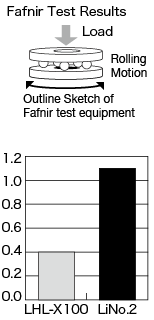

Excellent load-carrying capacity and wear resistance

Excellent migration property

Fretting Resistance Test Utilizing the ASTM F4170 Fafnir Test

| Shaft : | ANDREWS W 5/8 |

| Weight : | 2450N (Ball 9pcs, Surface Pressure : 1.9GPa) |

| Rolling Angle : | 12? (Rolling Width : Approx. 3.0mm) |

| Rolling Cycle : | 3.4Hz(Approx. 200 cycles) |

| Time Duration : | 10h |

| Temperature : | Room temperature |

| Warm-up Operation : | No |

| Amount of lubricant applied : |

1.0 + 0.05g per bearing ? 0.2 + 0.01g |

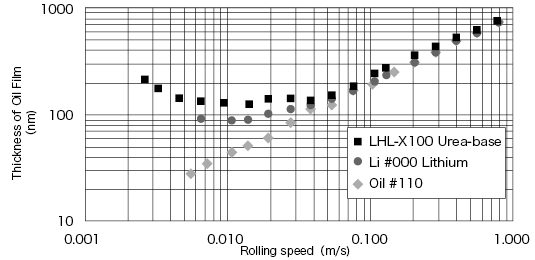

Thickness of Oil Film (LHL-X 100・Lithium-based Grease・Oil)

LHL-X 100 Special Urea Grease provides thicker oil films in slow rolling speed range.

Having tested the performance of lubricants by focusing on thickness of oil film provided by each lubricant, we found that the oil films become thinnest when rolling speeds become 0m/s ( or all most 0m/s). Both greases provide thicker oil films than oil. LHL-X 100, however, (a special urea grease)provides even thicker oil films than lithium grease. The test results prove that LHL-X 100 prevents oil film deficiencies more effectively and efficiently which eliminates stick slip.